Please message us after each purchase to let us know what two radius insert

sets you would like with your jig.

For luthiers who prioritize precision and adaptability, we offer the

Fretboard Radius Router Jig. Utilizing 3D printing technology, this tool

provides accurate and consistent fretboard radiusing.

This jig will work with fretboards up to 3 inches wide.

We recommend a long straight bit with a 3/8" cutting diameter such as the

Whiteside 1023.

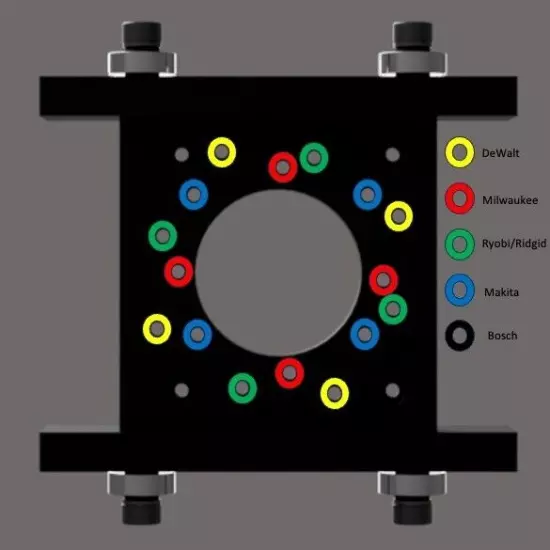

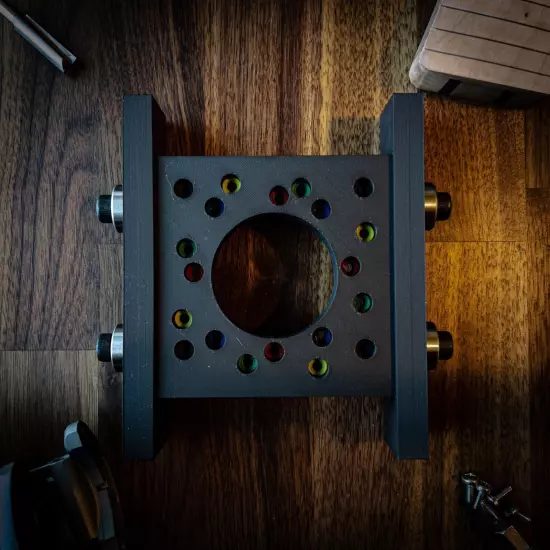

Our jig is tailored to fit popular compact router models such as the

Milwaukee M18 Fuel, Ryobi P601 One+, Dewalt DWP611, Bosch PR20EVS, Makita

RT0701C, and Ridgid R2401. If your router isn't listed, we encourage you to

contact us for potential custom base solutions.

The jig comes with the option to select two sets of radius inserts, covering

a spectrum of fretboard designs. Should you not find the radius you're looking

for, we offer custom radius inserts upon request to meet specific requirements.

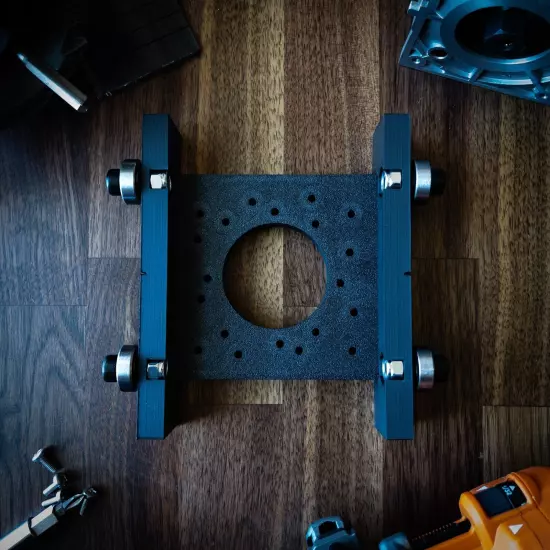

Inside the package, you'll discover the Fretboard Radius Router Jig body,

router base, and your chosen radius inserts.

Designed with dedication to the craft of lutherie, this tool aims to deliver

both reliability and precision. If you have queries or need additional

information, we're here to assist.

Instructions:

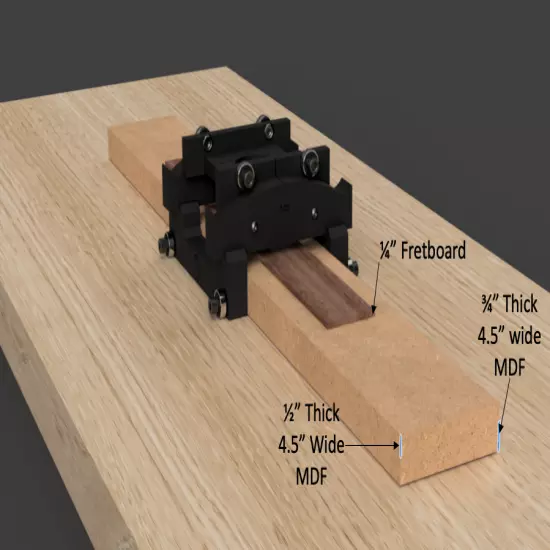

1.Setting the Height: Choose the thickness of your preferred board material

MDF, plywood, or hardwood) such that, when placed on your working surface,

there's a 1.5-inch height from the top of the surface to the top of the

fretboard. Importance of 1.5-inch Height: The radius inserts are designed to

compensate for the distance from where the router base contacts the radius

insert to the top of the fretboard. This height ensures an accurate radius

replication. If the setup has a height less than 1.5 inches, there's a risk

that the resulting radius on the fretboard may be rounder than intended.

2. Board Preparation: Cut the chosen board material to a width of 4.5

inches. Ensure the edges are straight and the board is free from defects.

Securing the Materials:

3. Use double-sided tape to affix the board to your workbench securely.

4. Positioning the Fretboard: Center the fretboard onto the affixed board,

ensuring even spacing on all sides. Once positioned correctly, use double-sided

tape to secure the fretboard in place. Note: Carefully inspect the fretboard

to verify there are no raised sections or uneven areas that might interfere

with the routing process.

5. Attaching the Jig: Attach the jig to the router base using the provided

screws, ensuring a firm and secure fit.

6. Installing Radius Inserts: Slide the desired radius inserts into the slot

located in the jig's body. Once properly positioned, tighten the set screws to

secure the inserts in place.

7. Placing the Jig Body: Position the Fretboard Radius Router Jig body onto

the setup constructed in steps 1-4.

8. Positioning the Router: Place the router base onto the jig body, ensuring

it aligns correctly and sits stably. Make sure all four bearings on the router

base are making contact with the radius insert for accurate routing.

9. Centering the Router: Align the router using the center lines provided on

both the router base and the radius insert.

10. Adjusting the Router Bit: Carefully lower the router bit until it barely

touches the fretboard. We advise against using a spiral bit for this process.

Opt for a straight bit for the best results.

11. Starting the Routing Process: Slide the jig in a manner that the router

bit is clear of any wood. With the bit in a clear position, safely turn the

router on, readying it for the routing process.

12. Routing the Fretboard: Begin routing the fretboard. Ensure the router

base bearings maintain contact with the radius insert at all times. Move with

the grain of the wood. After completing each pass, slide the router base

laterally to start a new path, ensuring full coverage of the fretboard surface.

sets you would like with your jig.

For luthiers who prioritize precision and adaptability, we offer the

Fretboard Radius Router Jig. Utilizing 3D printing technology, this tool

provides accurate and consistent fretboard radiusing.

This jig will work with fretboards up to 3 inches wide.

We recommend a long straight bit with a 3/8" cutting diameter such as the

Whiteside 1023.

Our jig is tailored to fit popular compact router models such as the

Milwaukee M18 Fuel, Ryobi P601 One+, Dewalt DWP611, Bosch PR20EVS, Makita

RT0701C, and Ridgid R2401. If your router isn't listed, we encourage you to

contact us for potential custom base solutions.

The jig comes with the option to select two sets of radius inserts, covering

a spectrum of fretboard designs. Should you not find the radius you're looking

for, we offer custom radius inserts upon request to meet specific requirements.

Inside the package, you'll discover the Fretboard Radius Router Jig body,

router base, and your chosen radius inserts.

Designed with dedication to the craft of lutherie, this tool aims to deliver

both reliability and precision. If you have queries or need additional

information, we're here to assist.

Instructions:

1.Setting the Height: Choose the thickness of your preferred board material

MDF, plywood, or hardwood) such that, when placed on your working surface,

there's a 1.5-inch height from the top of the surface to the top of the

fretboard. Importance of 1.5-inch Height: The radius inserts are designed to

compensate for the distance from where the router base contacts the radius

insert to the top of the fretboard. This height ensures an accurate radius

replication. If the setup has a height less than 1.5 inches, there's a risk

that the resulting radius on the fretboard may be rounder than intended.

2. Board Preparation: Cut the chosen board material to a width of 4.5

inches. Ensure the edges are straight and the board is free from defects.

Securing the Materials:

3. Use double-sided tape to affix the board to your workbench securely.

4. Positioning the Fretboard: Center the fretboard onto the affixed board,

ensuring even spacing on all sides. Once positioned correctly, use double-sided

tape to secure the fretboard in place. Note: Carefully inspect the fretboard

to verify there are no raised sections or uneven areas that might interfere

with the routing process.

5. Attaching the Jig: Attach the jig to the router base using the provided

screws, ensuring a firm and secure fit.

6. Installing Radius Inserts: Slide the desired radius inserts into the slot

located in the jig's body. Once properly positioned, tighten the set screws to

secure the inserts in place.

7. Placing the Jig Body: Position the Fretboard Radius Router Jig body onto

the setup constructed in steps 1-4.

8. Positioning the Router: Place the router base onto the jig body, ensuring

it aligns correctly and sits stably. Make sure all four bearings on the router

base are making contact with the radius insert for accurate routing.

9. Centering the Router: Align the router using the center lines provided on

both the router base and the radius insert.

10. Adjusting the Router Bit: Carefully lower the router bit until it barely

touches the fretboard. We advise against using a spiral bit for this process.

Opt for a straight bit for the best results.

11. Starting the Routing Process: Slide the jig in a manner that the router

bit is clear of any wood. With the bit in a clear position, safely turn the

router on, readying it for the routing process.

12. Routing the Fretboard: Begin routing the fretboard. Ensure the router

base bearings maintain contact with the radius insert at all times. Move with

the grain of the wood. After completing each pass, slide the router base

laterally to start a new path, ensuring full coverage of the fretboard surface.

| Country/Region of Manufacture | United States |

|---|---|

| Type | Luthier Tools |