This listing complies with the store's air gun guidelines found here and I

will only sell and ship air guns to buyers in jurisdictions where permitted by

applicable laws -

http://pages..com/help/policies/firearms-weapons-knives.html

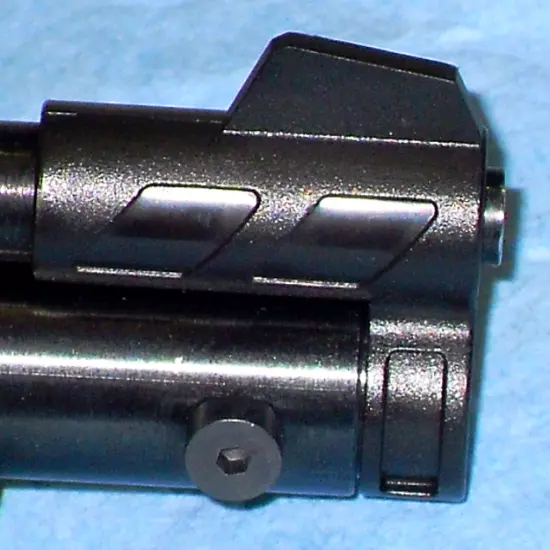

This listing is for one custom pivot pin with nut, other parts shown for

reference only.

PLEASE READ THE NOTES AND INSTRUCTIONS BELOW, THIS PART REQUIRES TOOLS AND

FITTING.

This part is made of super-strong grade 12.9 alloy steel. The pin fits a

3/32" hex, the 12-point socket of the nut fits a 3/16" hex wrench, no hex

wrenches or other tools included. These parts have a durable black-oxide

finish, the pin-shaft is polished raw steel. The pin has a shoulder that stops

the nut at 3/4" which is the same as the outside tube diameter, this prevents

the front of the tube from expanding when force is applied to the pump-lever

and also prevents over-compressing the front of the tube. This is the strongest

and most stable pin design available in the industry.

IMPORTANT, the following two paragraphs are critical for installing a solid

pivot-pin :

The hole in the unmodified factory tube is 3/16" slip-fit on the left side

and 3/16" press-fit on the right side. This solid pin requires a 3/16" slip-fit

on both sides. A standard 3/16" drill bit can be used to enlarge the hole to

the correct size. The hole on the left side is usually large enough to fit the

drill bit to line up straight with the right side to keep them aligned

correctly. The sharp edges of the holes inside the tube should be deburred

after drilling to avoid damaging the valve and piston seals. This can be done

with a small round hobby file or a 2" x 2" piece of 300-400 grit sandpaper

rolled tightly into a tube to use as a file. Insert the file through the

outside of the hole at an angle and file lightly around the inside edge until

it is dull all the way around, do this to both holes, then file or sand the

inside surface around the holes reaching in from the front of the tube to make

sure everything is smooth. Do not remove a lot of metal, just enough to dull

the sharp edge and smooth the internal area around the holes.

Some tubes have the pivot-pin holes further back than others. Older tubes

tended to have them closer to the front of the tube, newer tubes tend to have

them back further which causes the barrel band holes to be slightly off-center

too far forward) for the pivot pin to fit through easily. With the factory

roll-pin you can simply force the pin through and it will compress to fit. With

this solid pin you may have to file the front of the tube back slightly until

the holes align. This is very easy to do, only a few file strokes are needed in

most cases, a few dozen in other cases. Be very careful to keep filings out of

the tube where they can cause damage to the seals and valve, stuffing a piece

of rag into the tube before starting this work and removing it afterwards helps

keep filings and grit out of the tube, flushing the tube out with rubbing

alcohol is a good idea also, the best way is to remove all parts from the tube

so it can be cleaned and reassembled correctly afterwards.

will only sell and ship air guns to buyers in jurisdictions where permitted by

applicable laws -

http://pages..com/help/policies/firearms-weapons-knives.html

This listing is for one custom pivot pin with nut, other parts shown for

reference only.

PLEASE READ THE NOTES AND INSTRUCTIONS BELOW, THIS PART REQUIRES TOOLS AND

FITTING.

This part is made of super-strong grade 12.9 alloy steel. The pin fits a

3/32" hex, the 12-point socket of the nut fits a 3/16" hex wrench, no hex

wrenches or other tools included. These parts have a durable black-oxide

finish, the pin-shaft is polished raw steel. The pin has a shoulder that stops

the nut at 3/4" which is the same as the outside tube diameter, this prevents

the front of the tube from expanding when force is applied to the pump-lever

and also prevents over-compressing the front of the tube. This is the strongest

and most stable pin design available in the industry.

IMPORTANT, the following two paragraphs are critical for installing a solid

pivot-pin :

The hole in the unmodified factory tube is 3/16" slip-fit on the left side

and 3/16" press-fit on the right side. This solid pin requires a 3/16" slip-fit

on both sides. A standard 3/16" drill bit can be used to enlarge the hole to

the correct size. The hole on the left side is usually large enough to fit the

drill bit to line up straight with the right side to keep them aligned

correctly. The sharp edges of the holes inside the tube should be deburred

after drilling to avoid damaging the valve and piston seals. This can be done

with a small round hobby file or a 2" x 2" piece of 300-400 grit sandpaper

rolled tightly into a tube to use as a file. Insert the file through the

outside of the hole at an angle and file lightly around the inside edge until

it is dull all the way around, do this to both holes, then file or sand the

inside surface around the holes reaching in from the front of the tube to make

sure everything is smooth. Do not remove a lot of metal, just enough to dull

the sharp edge and smooth the internal area around the holes.

Some tubes have the pivot-pin holes further back than others. Older tubes

tended to have them closer to the front of the tube, newer tubes tend to have

them back further which causes the barrel band holes to be slightly off-center

too far forward) for the pivot pin to fit through easily. With the factory

roll-pin you can simply force the pin through and it will compress to fit. With

this solid pin you may have to file the front of the tube back slightly until

the holes align. This is very easy to do, only a few file strokes are needed in

most cases, a few dozen in other cases. Be very careful to keep filings out of

the tube where they can cause damage to the seals and valve, stuffing a piece

of rag into the tube before starting this work and removing it afterwards helps

keep filings and grit out of the tube, flushing the tube out with rubbing

alcohol is a good idea also, the best way is to remove all parts from the tube

so it can be cleaned and reassembled correctly afterwards.

| Brand | Magnum Airpower LLC |

|---|---|

| MPN | Does Not Apply |

| UPC | Does not apply |