This listing complies with the store's air gun guidelines found here and I

will only sell and ship air guns to buyers in jurisdictions where permitted by

applicable laws -

http://pages..com/help/policies/firearms-weapons-knives.html

THIS LISTING INCLUDES TWO CUSTOM BREECH SCREWS ONLY

WE HAVE A SEPARATE LISTING THAT INCLUDES A T8 L-KEY WITH TWO OF THESE SCREWS

IF YOU NEED THE TOOL

These upgrade breech screws were designed by Magnum Airpower and

custom-manufactured exclusively for us, they are not available from any other

source. They are made of 410 stainless-steel heat treated to meet metric class

12.9 with a specified hardness of HRc 39-43. Their approximate tensile strength

is 185,000 PSI. They have a T8 Torx-socket and are a direct-fit replacement for

the original inner breech screw on all the models they are listed for. They are

3/16" long which is 1/16" shorter than the factory screw, it was made shorter

so it doesn't stick as far down into the tube as the original which we felt was

much longer than it needed to be. Crosman uses a longer screw that was readily

available from an industrial supplier to avoid the expense of having a

custom-length screw manufactured, that's also possibly why their screw has a

tiny .050" socket that rounds-out easily, it's what was cheap and readily

available.

Do not over-tighten the screw, snug it down only until the breech is firmly

against the tube with no wobble. If over-tightened the threads in the tube will

strip first, the screw threads are much stronger. If you hold the T8 L-key by

the shorter end and insert the longer end into the screw socket it's a lot

harder to apply enough force to strip the threads.

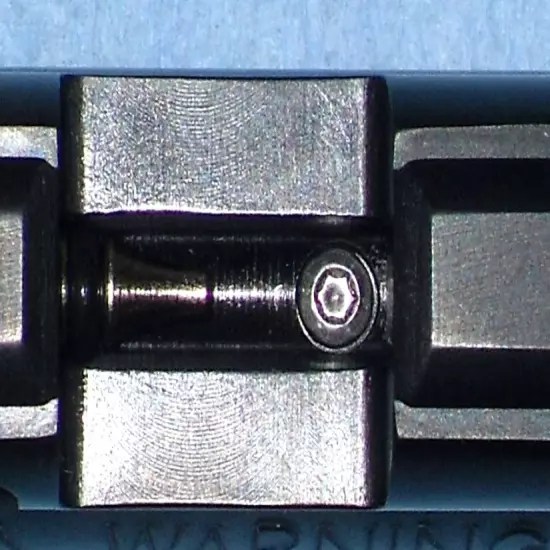

BREECH SCREW LOCATION: For Discovery, Maximus, 2300KT, 2400KT and some related

models you have to remove the rear breech and rear trigger frame screws, take

out the rear tube plug, then remove the bolt handle to push the bolt back far

enough to access the breech screw. We suggest putting a tiny amount of

medium-strength threadlocker on the bolt handle when you put it back on. They

tend to come loose otherwise, you only need to put it on finger tight. The

standard Crosman Steel Breech Kit, 13XX and many other models have the screw in

the position shown in the photo where it's easier to reach.

The following videos cover the Discovery model including how to remove and

install the breech. the store does not allow links to be active so you need to

copy the red link and paste it into the address bar above in your browser.

DISCOVERY DISASSEMBLY : https://youtu.be/woiQMwBbVxs

DISCOVERY REBUILD ( also covers some custom parts) :

https://youtu.be/TqDrNnTGPY8

CUSTOM RIFLE TRIGGER & CASING : https://youtu.be/uRCkcXnTKsE

will only sell and ship air guns to buyers in jurisdictions where permitted by

applicable laws -

http://pages..com/help/policies/firearms-weapons-knives.html

THIS LISTING INCLUDES TWO CUSTOM BREECH SCREWS ONLY

WE HAVE A SEPARATE LISTING THAT INCLUDES A T8 L-KEY WITH TWO OF THESE SCREWS

IF YOU NEED THE TOOL

These upgrade breech screws were designed by Magnum Airpower and

custom-manufactured exclusively for us, they are not available from any other

source. They are made of 410 stainless-steel heat treated to meet metric class

12.9 with a specified hardness of HRc 39-43. Their approximate tensile strength

is 185,000 PSI. They have a T8 Torx-socket and are a direct-fit replacement for

the original inner breech screw on all the models they are listed for. They are

3/16" long which is 1/16" shorter than the factory screw, it was made shorter

so it doesn't stick as far down into the tube as the original which we felt was

much longer than it needed to be. Crosman uses a longer screw that was readily

available from an industrial supplier to avoid the expense of having a

custom-length screw manufactured, that's also possibly why their screw has a

tiny .050" socket that rounds-out easily, it's what was cheap and readily

available.

Do not over-tighten the screw, snug it down only until the breech is firmly

against the tube with no wobble. If over-tightened the threads in the tube will

strip first, the screw threads are much stronger. If you hold the T8 L-key by

the shorter end and insert the longer end into the screw socket it's a lot

harder to apply enough force to strip the threads.

BREECH SCREW LOCATION: For Discovery, Maximus, 2300KT, 2400KT and some related

models you have to remove the rear breech and rear trigger frame screws, take

out the rear tube plug, then remove the bolt handle to push the bolt back far

enough to access the breech screw. We suggest putting a tiny amount of

medium-strength threadlocker on the bolt handle when you put it back on. They

tend to come loose otherwise, you only need to put it on finger tight. The

standard Crosman Steel Breech Kit, 13XX and many other models have the screw in

the position shown in the photo where it's easier to reach.

The following videos cover the Discovery model including how to remove and

install the breech. the store does not allow links to be active so you need to

copy the red link and paste it into the address bar above in your browser.

DISCOVERY DISASSEMBLY : https://youtu.be/woiQMwBbVxs

DISCOVERY REBUILD ( also covers some custom parts) :

https://youtu.be/TqDrNnTGPY8

CUSTOM RIFLE TRIGGER & CASING : https://youtu.be/uRCkcXnTKsE

| Brand | Magnum Airpower |

|---|---|

| MPN | Does Not Apply |

| UPC | Does not apply |